Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

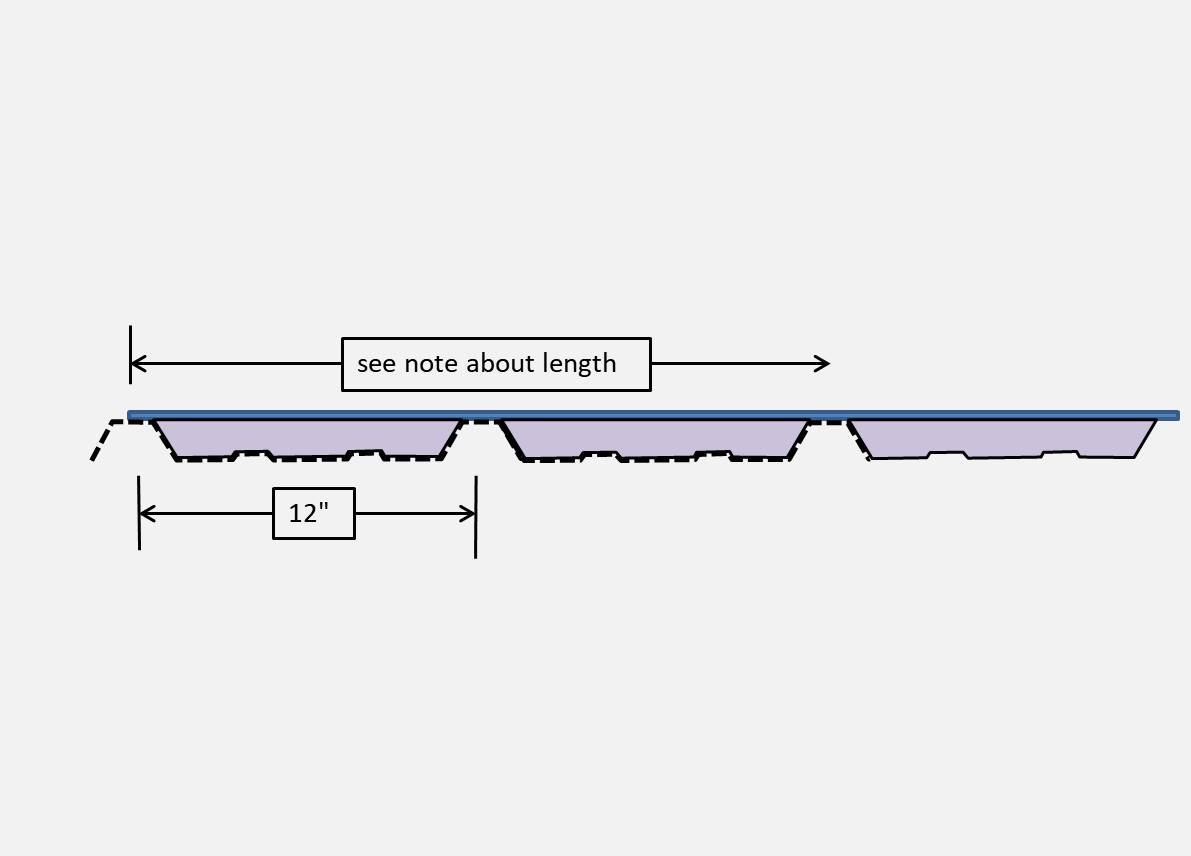

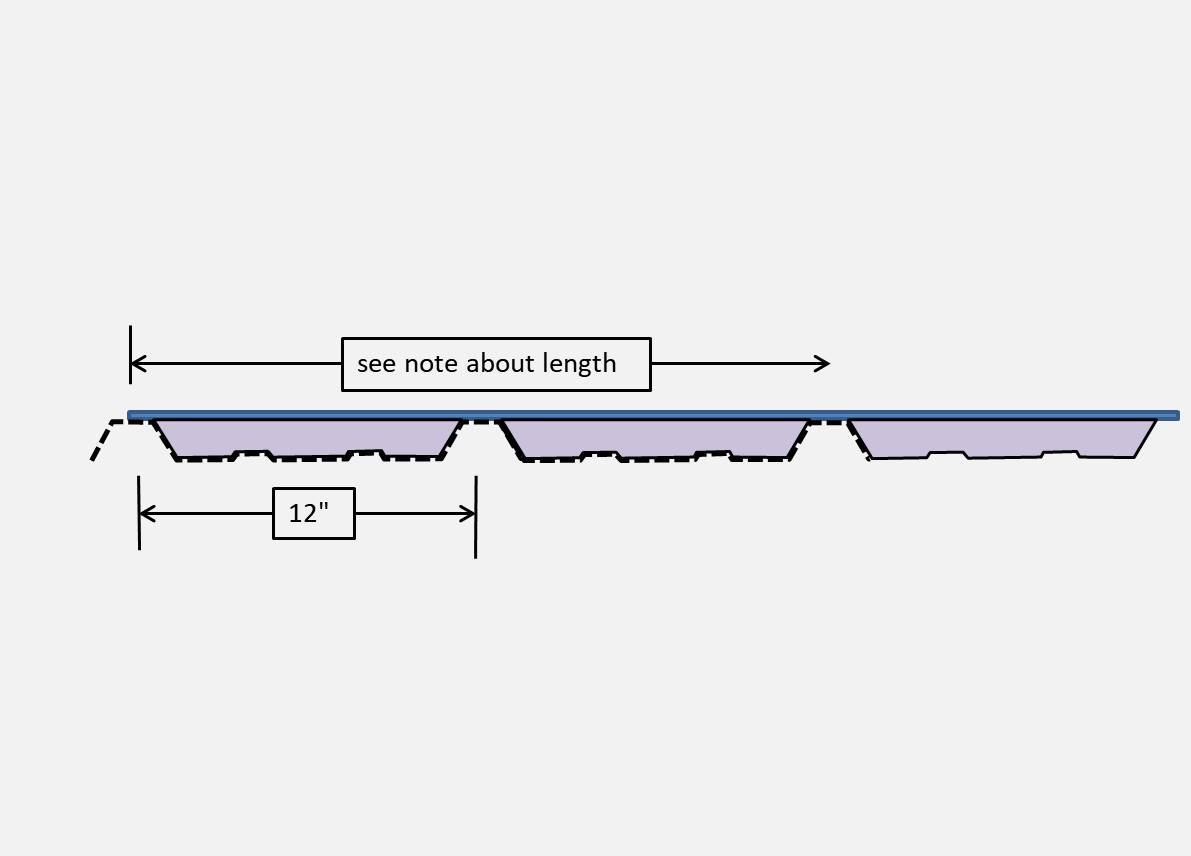

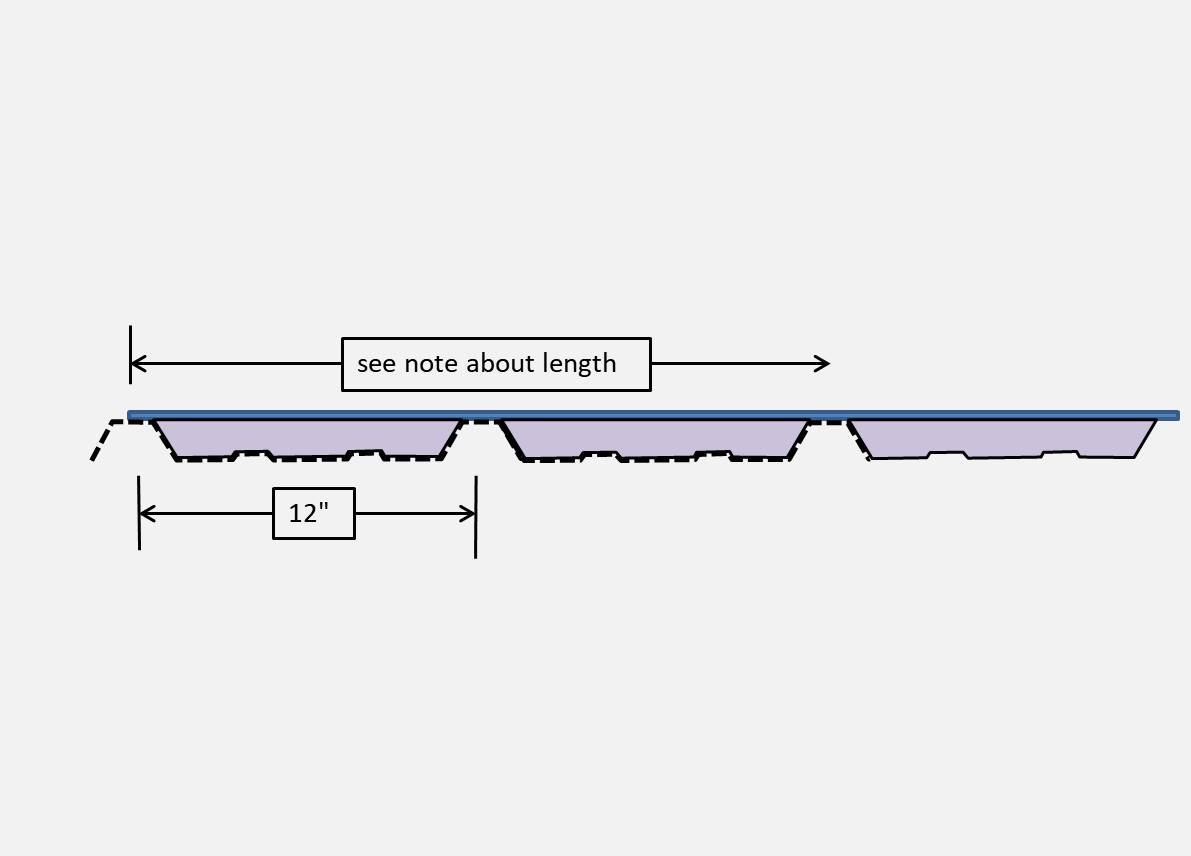

1201 EPS filler for Building Panels, exterior side, parallel to ridges

The 1201 filler is the extruded polystyrene that fills the void between the ridges up to the top of the major ridge crown. It is the filler material used for our Haslet Frames. It is made from EPS (extruded polystyrene) which is a dense, tough styrofoam.

Available for R-Panel, Ag-Panel, SM-Rib, and many other ridges (contact us).

The 1201 filler is the extruded polystyrene that fills the void between the ridges up to the top of the major ridge crown. It is the filler material used for our Haslet Frames. It is made from EPS (extruded polystyrene) which is a dense, tough styrofoam.

Available for R-Panel, Ag-Panel, SM-Rib, and many other ridges (contact us).

NOTE ON LENGTH:

Any length up to 10 ft can be ordered; however, keep in mind that positioning the horizontal pieces is dictated by the ridges on the building's siding. Unlike flat faying surfaces, there are no minor adjustments due to the "locked-in" position of the siding ridges.

Be sure to order ample length per the formula below such that any reposition takes into account the full 12 inch segment shift due to the distance between the ridges.

L (to order) = Length (required) + 12 inches

EXAMPLE:

Framing an exhaust fan cutout, the rough-in cutout is 30" wide. A frame will be installed around the cutout . Each side of the frame will be 5.5" wide. The total length of the horizontal pieces (see the top and bottom items in blue in the figure) will be 30 + 2 x 5.5 = 41 inch.

Because the rough-in cutout could fall anywhere in the panel ridge patter, the recommended length to order for the horizontal pieces is:

L (order) = 41 + 12 = 56 inches

Best is to send us your rough-in cutout dimensions. Feel free to email us or call for any questions: 817-939-5671